Currently Available Biosimilars—And Their Complications

Biosimilars for human growth factors and hormones have already been developed and brought to market in the E.U. These include epoietin, insulin, filgrastim, and somatatropin. These are complex molecules; for example, somatotropin has a molecular weight that is 100 times greater than aspirin. The advent of a less costly biosimilar, filgrastim (cf. Neupogen), resulted in a dramatic increase in the use of this agent in the U.K. On the other hand, the development of the erythropoietin biosimilar has faced many challenges. Seemingly small changes in manufacturing have led to dramatic consequences. For example, the tungsten-containing component of the rubber plunger that was used in the prefilled syringe resulted in unfolding of the protein. This change in structure led to the formation of antibodies to the biosimilar that cross-reacted with native erythropoietin. As a result, between 1998 and 2004, there were 175 cases of pure red-cell aplasia in patients taking the drug. The newly approved erythropoietin biosimilar (Omontys) was recalled due to patients developing allergic reactions, some of which were fatal.

The monoclonal antibodies (mAbs) and receptor fusion proteins display yet another order of magnitude in molecular weight and complexity compared to growth factors and hormones. One could easily imagine how a slight change in protein folding or glycosylation could produce a change in function or immunogenicity compared to the innovator biologic. In fact, there is historical precedent for this phenomenon. Lenercept, a p55 TNF receptor (TNF-RI) fusion protein, was developed at about the same time as etanecept (p75 TNF-RII). However, it never reached the marketplace due to a number of manufacturing problems that resulted in different glycosylation patterns and varied clinical efficacy.

Clinical trials of the biosimilar in humans will need to demonstrate that it is indeed “biosimilar.”

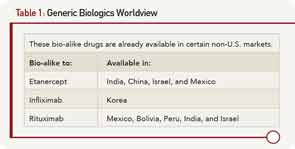

Biosimilars for the U.S. Market

Assuming that a biosimilar manufacturer can derive the exact amino sequence of a mAb or fusion protein receptor (apparently possible, but incomprehensible to the nonscientist), the very manufacturing process is critical. In fact, when the Food and Drug Administration (FDA) approves an innovator biologic DMARD, the approval applies to this precise production process. Any subsequent change in the manufacturing process must be approved by the FDA, which has the power to require additional studies, including clinical trials, to verify the safety and efficacy of the new process.

FDA guidance documents based on the Biologics Price Competition and Innovative Act specifically stipulate the requirements for successful registration of a biosimilar in the U.S. At least two separate clinical studies of immunogenicity are required, pre- and postapproval. At least one study will be required for pharmacokinetics and pharmacodynamics, as well as additional analytical studies with details to be specified, based on the product. Clinical trials of the biosimilar in humans will need to demonstrate that it is indeed “biosimilar,” e.g., “equivalent” in terms of efficacy, pharmacokinetics and pharmacodynamics, immunogenicity, and with a safety profile very similar to the innovator product. Finally, extrapolation from one clinical indication to other indications that have been approved for the innovator will be decided on a case-by-case basis.